What is a corn conditioner, how does it work and how to make such a unit with your own hands

For quick and high-quality harvesting of corn for the winter, you need a conditioner. This unit reduces labor costs and improves product quality. Making a conditioner with your own hands does not take much time, but it will significantly save on the purchase of equipment.

From the article you will learn what a corn conditioner is, what is the principle of its operation and the stages of production.

The content of the article

What is corn conditioner

A conditioner, or a crusher, is a device designed for crushing fresh grain.

For crimping, a grain of wax ripeness is used. It has more useful components than dried.

Components

Main parts of the conditioner:

- working part - usually it is installed directly on the engine, it is responsible for uniform grain processing;

- frame - it is made of metal, is responsible for the stability of the structure;

- body - a structure that covers and protects all internal mechanisms;

- bunker for receiving raw materials - metal container;

- internal flap - allows you to control the volume of grain flow into the working section;

- motor and drive - a motor powered by electricity;

- unloading auger - a metal container into which processed grain falls.

Types of conditioners, depending on the working part:

- Cheek. Two plates act as a working part. In the process of crushing, one is fixed motionless, and the second makes rotational movements. The grain is crushed while it is between the plates.

- Rotary. The crushing of corn grain occurs due to rotors and hammers fixed on them.

- Conical. The cone serves as the working part. When the cone rotates, the grain, falling on it, is crushed.

- Molotkovaya. The main principle is in the work of hammers fixed on hinges. When the grain enters the working section, the grain splits from impacts.

- Roller. The grain is crimped by passing them through the rolls.

Principle of operation

The collected and cleaned corn grain is poured into the raw material receiving hopper. It passes through the working part, in which it is processed. The movement is driven by a drive. Processed grain moves into the unloading auger. Where is it taken from for cooking stern... The quality of processing depends on the type of the working part.

Important! During work, make sure that stones and other foreign materials do not get into the working part - this will damage the working part of the conditioner.

How the grain grinder works

Grain begins to fall asleep when the valve is closed. After the grain has entered the receiving hopper, the valve is opened little by little. The grain falls into the working chamber, and the grinding process begins with the help of rotating knives.

After grinding, the grain is passed through a sieve. The hole diameter controls the grain size. The crushed grain enters the raw material receiving hopper.

Important! The working part wears out during operation, so it requires constant maintenance.

For chopping up stems

The process of milling corn tops is similar to milling the cobs.

The principle of operation of the stalk chopper:

- The stems are loaded into a rectangular hatch located in the side of the shredder.

- The haulm passes through the knives of the working part

- Crushed plant residues are fed to the receiving hopper.

For grinding corn on the cob

The process of milling corn in heads of cabbage is simple. The economic effect is achieved by increasing the performance of the grinder.

Principle of operation:

- Corn cobs are placed in a rectangular hatch.

- Due to the traction force, they enter the working section, where the radially located knives are located.

- After crushing, the raw material enters the receiving hopper and is ready for use.

Purchase

Before making a purchase, pay attention to the characteristics of the conditioner:

- Appointment. For operation on small subsidiary farms or for personal purposes, a factory or self-assembled hammer crusher is suitable. Large farms will have to purchase a factory model.

- Power. The device is chosen based on the maximum volume of grain that needs to be processed.

- Performance. For small farms, it is not necessary to purchase a unit with a high performance. The main thing is to determine how much ready-made feed the poultry and livestock will need.

- Dimensions. Before purchasing a shredder, you must choose a place where it will be stored.

The best manufacturers

We suggest considering the most popular models.

"Electromash IZ-05M"

Designed for medium-sized farms. Engine power: 800 kW. Grain processing productivity: 170 kg / h. Weight: 6 kg. Receiving hopper volume: 5 l.

"Piggy"

The main advantages of the model are its small design, reliable materials of manufacture and ease of use. Manufacturer: Russia. The receiving hopper is designed for 10 kg. Productivity: 300 kg / h of grain. Power consumption: 1.9 kW.

"Farmer IZE-25M"

Designed for medium-sized farms. Engine power: 1300 kW. Productivity: 400 kg / h of grain. Weight: 7.3 kg. Grinding adjustment. Without receiving hopper.

"ThermMix"

The advantage of the shredder is its low power consumption. Engine power: 500 kW. Productivity: 500 kg / h of grain. Device warranty: 3 years. Weight: 10 kg. Receiving bunker: 35 l.

Important! The main characteristic when choosing a model is the performance of the unit. The larger the farm, the higher the productivity should be.

Where to buy and how much does it cost

There is a huge selection of manufacturers and sites for the sale of agricultural machinery.

Where to buy a corn conditioner:

- online stores;

- construction stores;

- special bases of agricultural equipment;

- purchase of a used device at the Avito site or other similar ones;

Or the device can be made by hand.

The cost of a corn conditioner depends on the mechanism of action and performance:

- The cheapest and easiest to operate are hand conditioners. Their cost starts from 2000 rubles. The disadvantage of such conditioners is low productivity.

- The cost of electrical appliances starts at 15,000 rubles. The price varies depending on power, performance and dimensions.

How to do it yourself

A hand-made conditioner is suitable for personal use or small farms.

The advantages of a homemade unit:

- low cost;

- confidence in the reliability of the design.

Disadvantages:

- low performance compared to purchased ones;

- unpresentable appearance.

What you need: what materials can you make such a device

To do quality work you will need:

- motor with a power of about 1 kW;

- metal sheet 3 mm thick;

- hardened steel for the working part;

- bolts, washers and nuts;

- any container of suitable size as a receiving hopper.

To complete the work, you will need tools:

- welding machine;

- locksmith tools;

- grinder with a cut-off wheel;

- electric drill;

- grinding machine.

Blueprints

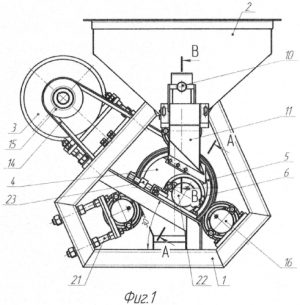

The grain crusher consists of the following units:

- gate valve for regulating grain supply to the working chamber;

- grain bin;

- on-off button of the electric motor;

- electric motor;

- sleeve;

- axis;

- washer;

- nut;

- screw;

- base;

- working chamber body;

- container for crushed grain;

- metal mesh (sieve).

Crusher working chamber diagram:

- base;

- working chamber body;

- screw;

- sieve.

Step-by-step instruction

Stages of making a crusher with your own hands:

- Take a sheet of metal and drill a hole in it slightly larger than the diameter of the motor shaft.

- Bolt the engine to the sheet. The motor can be taken from a vacuum cleaner or water pump.

- Make a working chamber. Cut a strip 4 cm thick from a sheet of metal and bend a ring with a diameter of 30 cm.

- Weld the ring to the base.

- Attach the working part to the engine with a coupling.

- Make a knife. A knife from a lawn mower or grinder will do. The length of the working part is 1-2 cm less than the working chamber.

- Attach the knife to the sleeve with bolts.

- Install the coupling to the engine.

- Attach the sieve to the bottom with studs and nuts. To make it, take a metal mesh with 3 mm holes.

- Install the receiving hopper. Make a hole about 3 cm in diameter at the top of the cooking compartment. Weld any cone-shaped container to the hole and make a valve. It will serve to adjust the supply of grain to the working part of the hopper.

- Place the finished product on a container that will become a raw material receiving bin.

Reviews

Buying a corn conditioner is a big step for small farms. In the reviews, those who made this device themselves share their achievements.

Vladimir, Tyumen: “I inherited a very simple one from my father. He did it in due time. How many years have passed, I still use it. Everything suits me".

Ramil, Ufa: “My experience with grain crushers is five years. During this time, I came to the conclusion that it is easier to make the device with your own hands. If you have experience using tools, then everything is easy, you only need to buy an engine. Recently made it myself. I threw out the old crushers. "

It is interesting:

Characteristics and description of a hybrid of corn seeds Krasnodar 291 AMV.

How to soak corn for planting and grow a rich harvest from ready-made seeds.

Conclusion

The corn conditioner is an essential and easy-to-use device on the farm. The purchase of such a unit will greatly facilitate the life of livestock breeders. Having decided on a suitable model, it is relatively easy to make a conditioner with your own hands. This will save money on the purchase and use a convenient device for a long time.